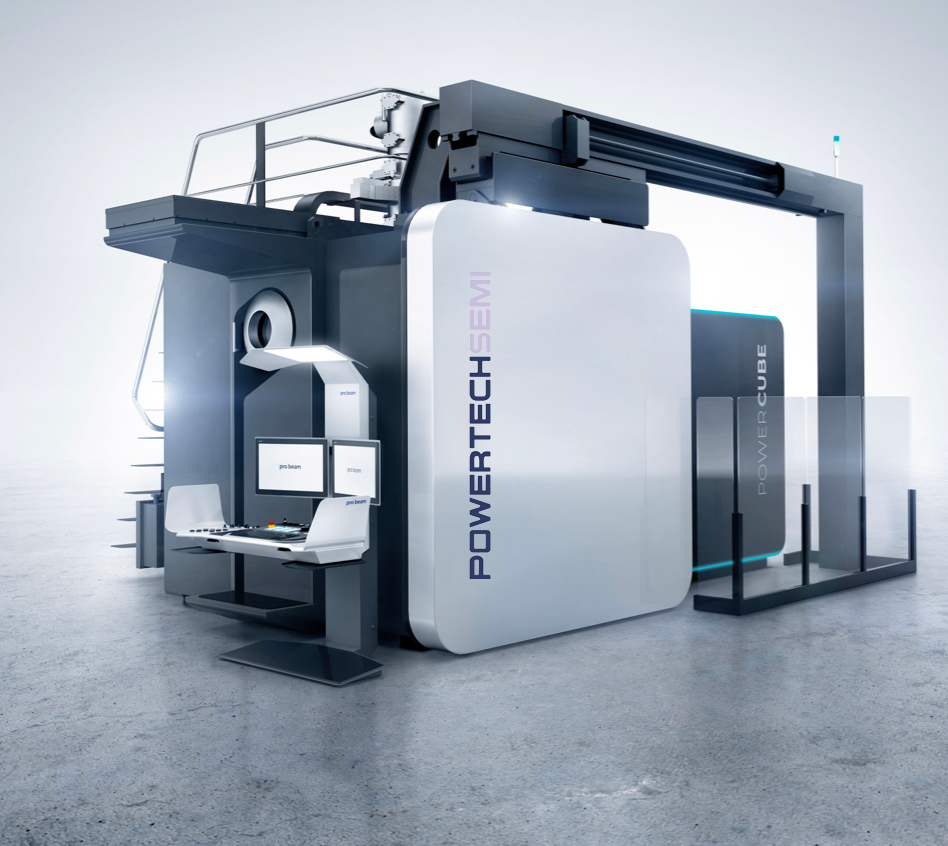

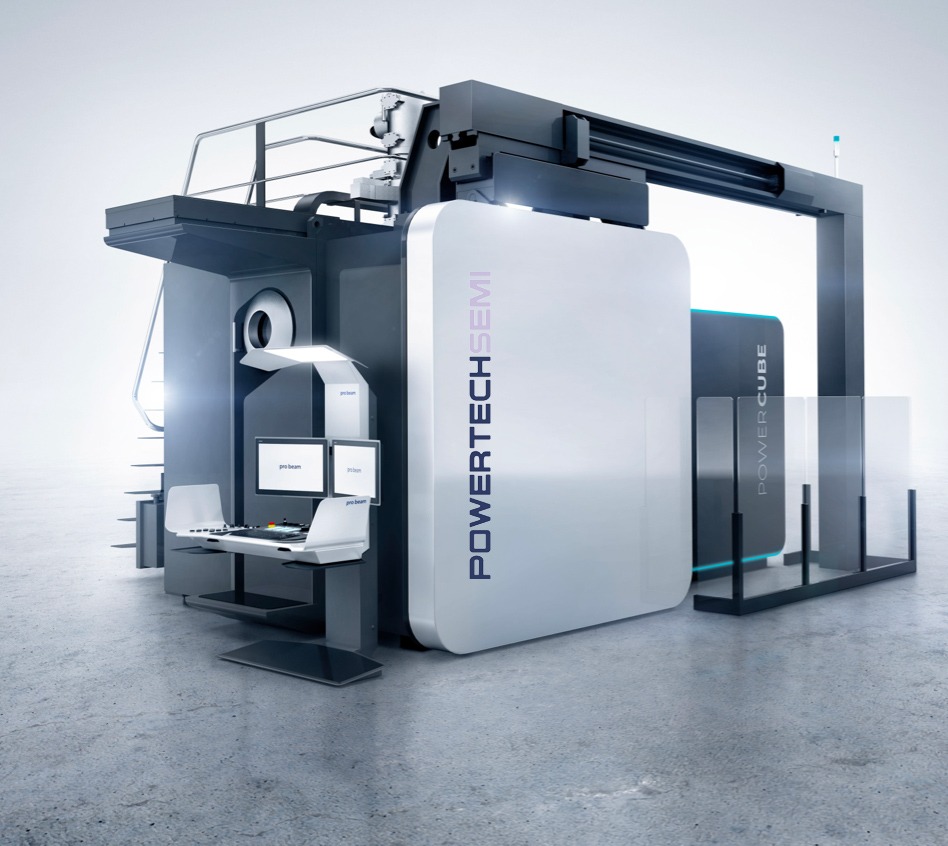

Direction detection station1

Designed and developed based on the needs of the semiconductor industry, using stable industrial cameras and industrial control computers, with accurate and error free digital transmission, fast response, clear capture, and complete reliability

|

precise |

Go quickly |

clearness |

reliable |

| model | Direction detection station |

| Product advantages | Power management category; Digital consumer goods; Audio category; Automotive, energy-saving and environmentally friendly electronics; Special or customized ICs and wafer testing |

| main features |

Designed and developed based on the needs of the semiconductor industry, using stable industrial cameras and industrial control computers, with accurate and error free digital transmission, fast response, clear capture, and complete reliability. • Fully meet the highest speed requirements; Handler; Our production speed and complete testing stations meet various testing needs of our customers. QV; A series of detection systems with configurable detection stations including: 3D; Detection station, printing station, tape weaving station, direction station, etc. This system can be paired with various models; Handler;, The detection scope covers various semiconductor devices, such as SOT23, SOD123, SOD323, and; SOD523; SOD923, SMA, SMB, SMC, SOD882 (1006), TO92, TO252, SOD129, MBS, SOP8L; The software system provides a Chinese and English interface, multi-level permission control, and a high degree of automation. Software System; 100%; Collaborative research and development, following the machine vision detection process, optimizing combinations and making them easy to operate and apply. All parameters of industrial cameras, such as shutter time, gain, contrast, and light source brightness, can be adjusted through software. • QV A series of machine vision recognition systems, designed for various packaging devices in the semiconductor industry, to perform typography and 2D printing on product pins and plastic packaging bodies; Pins, 3D; Comprehensive and high-precision image inspection of surface defects on pins and plastic packaging bodies. Convenient application, easy operation, stable system operation, and improving customer production capacity. Timely detect the accuracy of various devices in the semiconductor industry to improve production efficiency. Perform calibration quickly, ensure zero defect rate, and improve production quality. |

| Function |

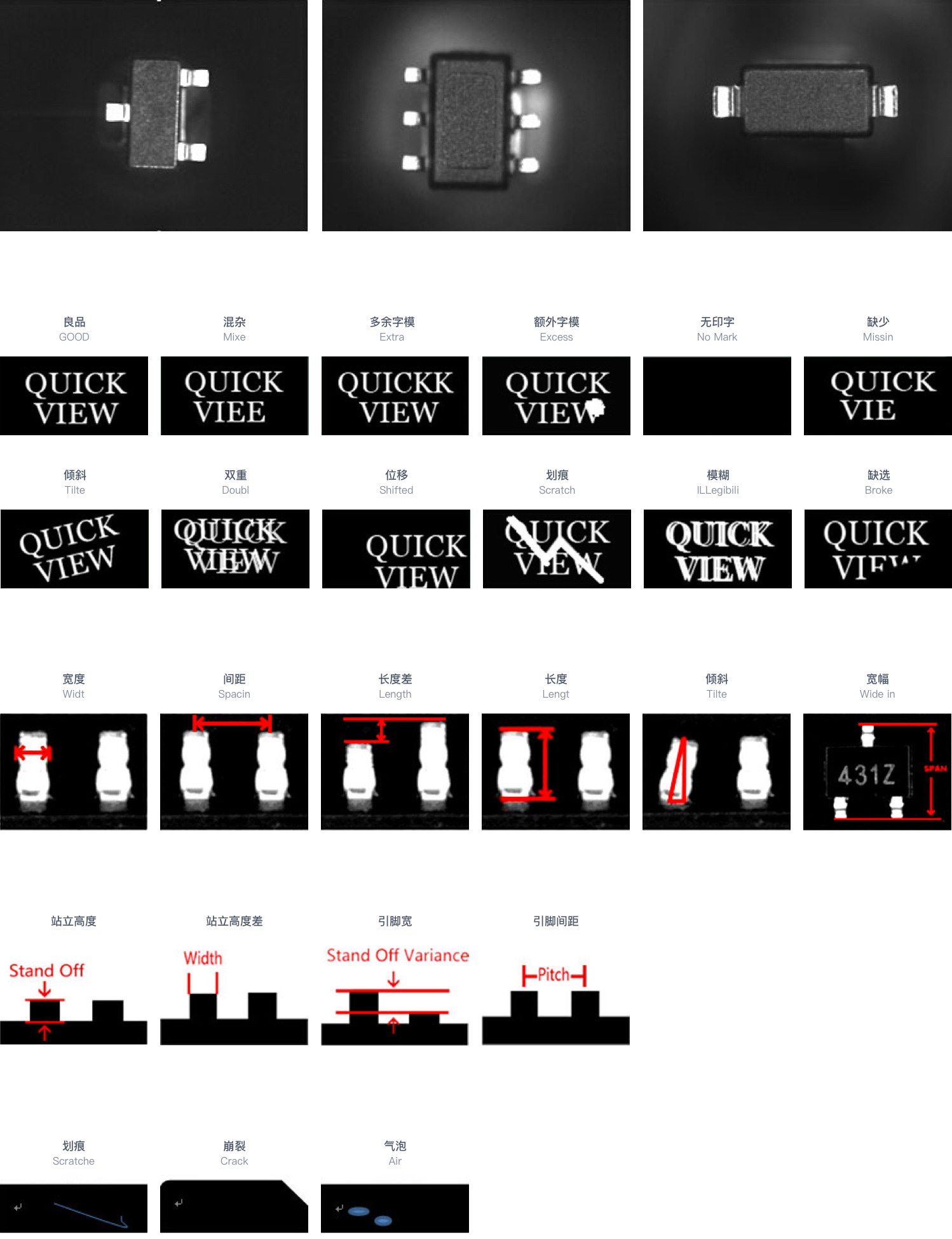

Detect the surface seal content of the device (typographical errors, multiple words, missing words, stains, offsets, blurred reprints, scratches, plastic seal cracking, etc.) Detect device pin information (direction, pin length, pin width, pin spacing, pin offset, etc.) |

| Basic configuration | CCD camera, industrial lens, LED light source, mechanical structural components |

| SI detection | The minimum area is 0.7mm * 0.7mm, and the overall average grayscale difference is above 40 |

| GR&R | <10% |

Testing standards

|

|

No. 16 Guangming Avenue, New Light Source Industry Base, Nanhai National High tech Zone, Foshan City, Guangdong Province, China |

|

|

+86 757 83207313 (Sales) |

|

|

+86 757 83208786 (Sales) |

|

|

info@powertechsemi.com |

Copyright PowerTECH industrial Co., Ltd. Powertechsmemi.com © 2015 | Privacy policy | Sitmap 粤ICP备17127080号-1